We are evaluating the Apalis dual core industrial temp SOM. I have provided the datasheet to our mechanical engineer. He has these additional questions:

Can you request from the supplier the 2 thermal resistances listed below? Often these are not on the datasheet, but the manufacturer can provide them. With this information we could then track the actual junction temperature of the SOM in the thermal model.

- Junction-to-Board (theta Jb)

- Junction-to-Case (theta Jc) – They do list on their datasheet a Junction-to-Top with a typical and max value. Not sure if this is considered the Junction-to-Case, which is the common terminology.

Hi @nickluther

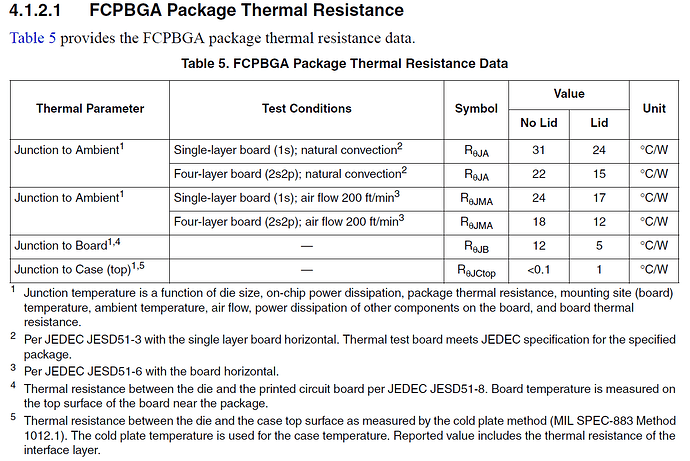

In the Datasheet of NXP, I was able to find the following information:

They provide typical values for the Junction-to-Board, as well as Junction-to-Case. However, these are just the theoretical values of the SoC. Unfortunately, we do not have real numbers for our computer module. This is really the only numbers I can provide you.

Thanks Peter. Is there any information available on the size and number of vias down to the center pad below the processor? If we had that, we could put together a low fidelity thermal model of our system.

-Nick

Hi @nickluther,

The Apalis iMX6 features a 10 layer PCB with a total of 3 ground layers. Additional to these solid ground layers, there are ground plane fillers on the top and bottom side of the PCB in order to help dissipating heat. The SoC has a total of 107 ground pins. Each of these ground pins has its dedicated micro via (laser drilled hole from layer 1 to 2). These vias connect the ground pins tightly to the ground plane on layer 2. Underneath the SoC there are about 70 buried vias (layer 2 to 9, 200um hole) which connect all internal ground layers together. There are many more buried ground vias on the complete PCB which makes sure the 3 ground layers are tightly connected together.

Thank you Peter! This is excellent information. We’re producing a lot of heat and a lot of airflow in our box, so we’re doing some thermal modeling. We are trying to validate our assumptions and prepare to increase our model fidelity if required, so this helps us gain confidence.